source:pogo pin release time:2022-03-23 Article author:sznbone Popular:POGO PIN

The pogo pin connector is a precision connector used in electronic products such as mobile phones, and is widely used in semiconductor equipment for connection. The female seat structure of the existing pogo pin connector uses a positioning plate and a fixing plate to clamp the contact terminals together. First, the contact terminals are positioned in the plate through the positioning plate, and then the contact terminals are clamped and fixed through the fixing plate. , This two-plate fixed structure is troublesome to install, increases the production cost, and is not firm; the female seat is generally fixed on the PCB board through the ear part through the screw, but the two-plate ear part is generally connected with the fixed plate. Connected, because the female seat structure of the pogo pin connector needs to be used in conjunction with the male seat, the male seat will often be plugged into the female seat during use, and the force can only be applied to the ears on the fixed plate when plugged. Therefore, the ear part of the existing structure is very easy to break, which shortens the service life of the female seat.

The purpose of the utility model is to provide a female seat structure of a pogo pin connector with firm structure, convenient installation, low production cost and long service life.

In order to achieve the above object, the utility model provides the following technical solutions:

A female seat structure of a pogo pin connector includes an integrally formed fixing seat, two ends of the fixing seat are respectively provided with fixing ears for fixing an external device, and mounting holes are arranged on the fixing ears, and the fixing ears are connected with A slope-shaped reinforcing rib is arranged at the connection of the fixing seat, a plurality of contact terminals are arranged in the fixing seat, and T-shaped through holes for installing the contact terminals are arranged in the fixing seat.

Further, there are 10 contact terminals.

Further, one side surface of the fixed seat is provided with two positioning protrusions for positioning during installation.

The fixing seat of the utility model is integrally formed by injection molding, so that the contact terminal can be directly installed on the fixing seat, and the contact terminals need not be clamped and installed together through the two-plate structure, and both ends of the fixing seat are also integrally formed by two fixing ears. , which is used to install the fixing base on the external device. The fixing ear is also formed together with the fixing base, so the thickness is greatly thickened, which improves the strength of the fixing ear, and is also provided at the connection between the fixing ear and the fixing base. The slope-shaped reinforcing rib further enhances the strength of the fixing ear; one side of the fixing seat is provided with two positioning protrusions for positioning during installation, which greatly improves the cooperation between the male seat and the female seat The fixing seat is provided with a T-shaped through hole for installing the contact terminal, and the contact terminal can be quickly installed in the fixing seat through the T-shaped through hole. The advantages of low production cost and long service life.

The utility model will be further described below in conjunction with the accompanying drawings:

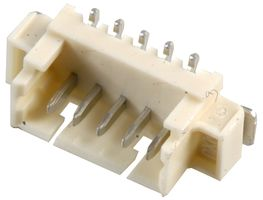

As shown in FIG. 1 to FIG. 3, a female base structure of a pogo pin connector includes an integrally formed fixing base 1, and both ends of the fixing base 1 are respectively provided with fixing ears 2 for fixing external devices. A mounting hole 3 is provided on the fixing ear 2, a slope-shaped reinforcing rib 4 is arranged at the connection between the fixing ear 2 and the fixing base 1, and a plurality of contact terminals 5 are arranged in the fixing base 1, and the fixing base 1 A T-shaped through hole 7 for mounting the contact terminal 5 is provided.

Further, there are 10 contact terminals 5 .

Further, one side surface of the fixing base 1 is provided with two positioning protrusions 6 for positioning during installation.

The fixing base 1 of this embodiment is first integrally formed by an injection mold, and after molding, a T-shaped through hole 7 for installing the contact terminal 5 and a fixing lug 2 for installing the fixing base 1 on the PCB are formed. The fixing lug 2 There is also a slope-shaped reinforcing rib 4 at the connection with the fixing base 1. In order to further strengthen the strength of the fixing ear 2, the connection between the fixing ear 2 and the fixing base 1 is broken; when installing, the fixing base 1 is firstly injection-molded by a mold. , the contact terminal is installed in the T-shaped through hole 7 on the side of the fixing base 1, and the tail end of the contact terminal 5 is bent downward and welded with the PCB board by SMI or DIP, and finally the fixing ear 2 is fixed on the PCB board by screws ; One side of the fixed seat 1 is provided with two positioning protrusions 6 for positioning during installation, and the protrusions 6 greatly improve the matching accuracy of the male seat and the female seat; In summary, the utility model is embodied It has the advantages of firm structure, convenient installation, low production cost and long service life.

The above is not intended to limit the technical scope of the present invention, and any modifications, equivalent changes and modifications made to the above embodiments according to the technical essence of the present invention still fall within the scope of the technical solutions of the present invention.

Read recommendations:

M2994 2.0*11.0(1A)RF Pogo Pin Production

M2885 2.0x1.3.5(1A)sewing thimble Wholesale

There are many doubts to pay attention to when looking for a magnetic connector manufacturer,welding