source:pogo pin release time:2022-05-25 Article author:yu Popular:POGO PIN

The pogo pins were never designed to have high speed data transfer. Let's take a look at how a pogo pin works, the mating end of the contact is usually gold plated and is usually a pointed point. The connection is made when this sharp point is pressed against the usually softer "mating contact". With no wiping action, as with standard pin and socket contacts, this design is more susceptible to contamination and corrosion, increasing the contact resistance across the connection, which makes low-voltage, high-speed signals more difficult to transmit.

The second design issue is the internal spring. The spring must make good contact with the plunger and base of the pogo pin, which can be problematic. Due to its helical design, the spring also introduces inductance into the contacts. Finally, to overcome the problems of using these contacts in a matched impedance system, each signal circuit must be surrounded by several ground circuits to isolate the contact's signal path from surrounding signal paths.

The pogo pin has long been established as a reliable and trusted technology for many applications. More recently, pogo pins have been used for more "permanent" connections in cell phones, laptops, computers, and other electronic devices. Many have relied on pogo pins for their durability, relatively small size, and their ability to absorb relatively large vertical mismatches between the connectors in which they are embedded. In a world where we want quick connections to batteries, laptop screens and I/O ports, they offer a very flexible solution.

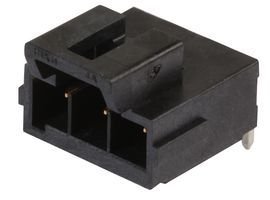

digital connector

general structure

The main purpose of fiber optic connectors is to connect optical fibers. Optical fiber connectors, which have been widely used in optical fiber communication systems, have many types and different structures. But on closer inspection, the basic structure of various types of fiber optic connectors is the same, that is, most fiber optic connectors are generally realized by high-precision components (composed of two pins and a coupling tube). Alignment of optical fibers.

In this method, the optical fiber is inserted and fixed in the ferrule, and after the surface of the ferrule is polished, alignment is achieved in the coupling tube. The outer components of the pins are made of metal or non-metal materials.

The butt end of the ferrule must be ground, and the other end usually uses a bend limiting member to support the fiber or fiber optic cable to relieve stress.

The coupling tube is generally made of two semi-synthetic and fastened cylindrical members made of ceramic or bronze and other materials, and is often equipped with a metal or plastic flange to facilitate the installation and fixation of the connector. In order to align the fibers as precisely as possible, the processing precision of the pins and coupling tubes is very high.

Read recommendations:

M2994 2.0*11.0(1A)RF Pogo Pin Production

M2467 3.5x9.5(1A)Water level spring pin price

M2915-1 1.81X6.0(5A)Data line spring needle Merchant

Analysis of the problem of abnormal gold plating of pogopin pogo pins