source:spring thimble release time:2020-10-15 Article author:sznbone Popular:POGO PIN

Spring thimble is a very common electronic connector. Its basic structure is mainly composed of turning needle tube, turning needle head and compression spring. There are curling edges at the nozzle of the needle tube to keep the needle in the needle tube. The contact force provided by the spring enables the electrical connection between the needle and the butt parts. It is believed that many people do not know how the spring thimble is welded. Let's follow Tyco Hanze's editor to understand how spring thimble connector is welded to PCB.

Magnetic suction connector

With the continuous development of the market and the continuous upgrading of products, more and more consumers are not only limited in the multi-functional products, but also require fashionable appearance and small and thin appearance. Spring thimble is a very fine probe, its volume can be made very small, so it can effectively reduce the weight of the connector, save space and make the appearance beautiful.

Thimble connector

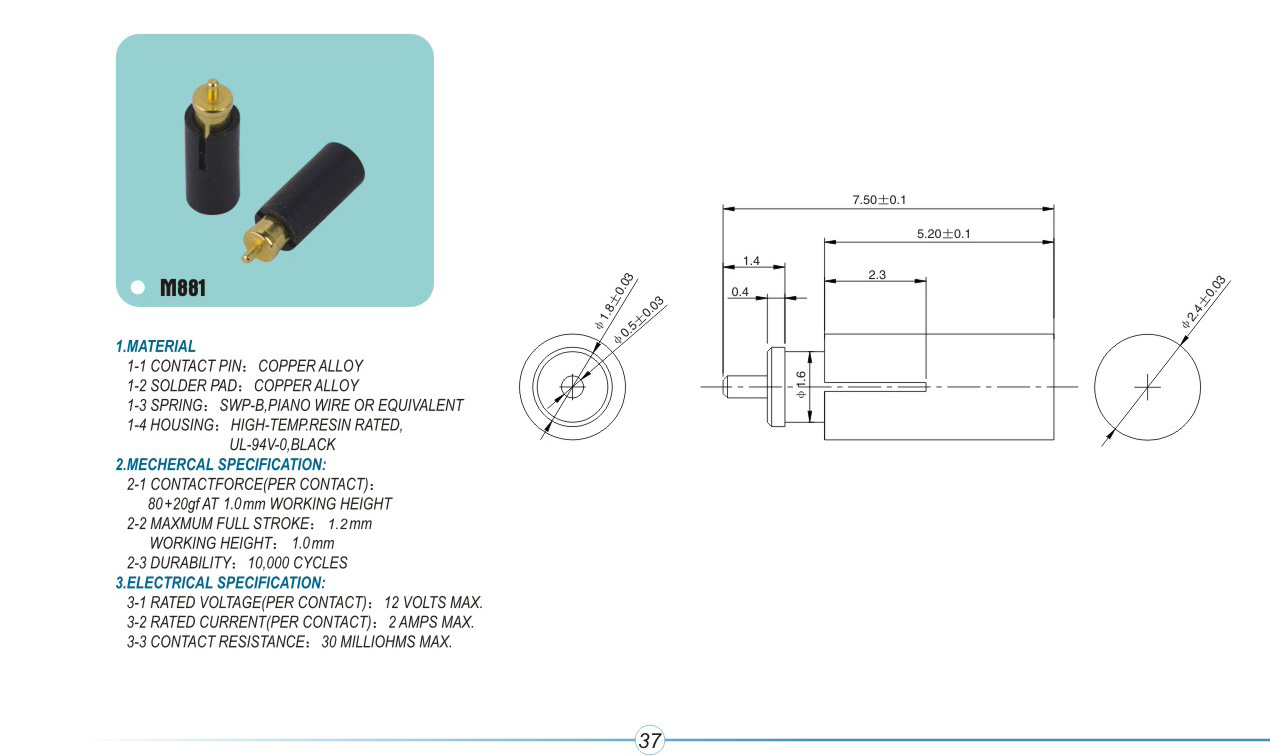

Many people do not know how spring thimbles are used in products and how they are welded on PCB boards. In fact, in the process of using the spring thimble, the male and female ends will be butted, and the spring needle will compress a certain stroke (the compression amount is 1.0 mm, and the elastic force is 70 g ± 20 g). It can be powered on, signal transmission and other functions.

Spring thimble can be welded on the PCB board to fix it, and can also be fixed in the product structure, which requires professional design engineers to solve these problems.

Shenzhen Wanchang Electronics Co., Ltd. was founded in 2004, set the mode of R & D, manufacturing and sales. It is located in Longgang District, Shenzhen. It has an independent factory building, covering an area of 9600 square meters. It is mainly engaged in the R & D and production of various pogopin and pogopin connectors, antenna shaft and self driving car bed parts. It can also produce and process according to customer's sample drawings, with more than 1000 kinds of products For customers to choose from, the products are mainly committed to UAV, intelligent robot, smart watch, computer, mobile phone, antenna, household appliances, medical equipment and other electronic products, constantly win the trust of customers with quality and service, and constantly create their own brand connecting the industry.

At present, the company's R & D personnel are experienced engineers with nearly 10 years of experience in the industry, and the total number of employees is 260. In order to meet the demand of market quality and provide customers with more solid quality assurance, the company passed the iso9007 quality system certification in 2007, and passed the ISO1400 environmental system certification in 2009.

The company has 120 lathes. There are 4 full-automatic assembly equipment and 110 semi-automatic assembly equipment. There are projector, quadratic salt spray tester, life tester, high temperature tester and load dynamic impedance tester. For the quality and delivery to provide a solid backing. The company has been maintaining excellent advantages in the field of pogopin connector products, which is recognized by some well-known enterprises at home and abroad, and has become their excellent connector supplier. And established a good reputation.

Read recommendations:

Elastic electrode M1090 5.2x22 (1A)Contact pin factory

Factors affecting the size of pogopin spring thimble

Pogo pin spring thimble waterproof method!Solder-cup Pogo Pin Processor